-

Client

Brothers Drinks

-

Sector

Food Production

-

Technology

Solar PV

-

System Size

316.52kWp

-

Estimated Annual Output

320,199kWh

-

Annual Carbon Savings

67,856kg

-

Payback Period

3 Years

-

25 Year Net Profit

£3.4 million

Client

Brothers Drinks is harnessing solar energy to power its manufacturing facility in Somerset, where it produces famous drink brands Babycham, Compton Orchard Cider, and Glastonbury Festival-favourite Brothers Cider.

Commercial cider production has been in the Showering family for 14 generations, dating back hundreds of years. The Showering brothers first started selling their cider at Glastonbury Festival in 1995. Today, Brothers Drinks is producing more than 140 million bottles per year, which are sold in pubs, bars and supermarkets throughout the UK. Solarsense has also installed several clean energy systems at Worthy Farm, including a solar PV system opposite the famous Pyramid Stage.

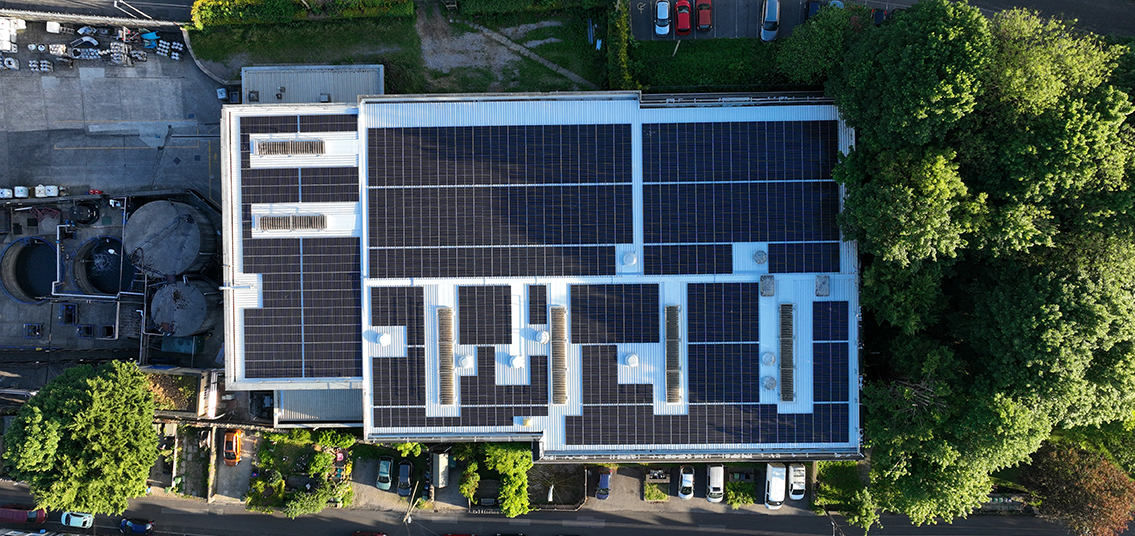

The Brothers Drinks solar PV system which was installed on the roof of the cider mill is part of an ongoing commitment to sustainability by the Showering brothers. They have also taken steps to minimise water usage, pioneer new recycling methods – enabling even the backing from their labels to be recycled – and operate a zero to landfill policy. The company already offsets its carbon emissions and supports biodiversity thanks to 150 acres of orchard just 5 miles away from the drinks production and manufacturing site.

From the client

“We had a few key factors that were critical to our decision-making process and whilst price was obviously important, the reputation of Solarsense both in terms of the quality of their work and environmental, social aspects swayed the choice in their favour. Several factors hindered the install initially, including limitation on export and working around a busy factory, but the main aspect we wanted to address was ensuring the condition of the roof was adequate to last the lifetime of the solar panels. Solarsense helped with this, were easy to work with and quick to respond to any queries through the whole process, providing good information at the sales stage and acting professional at all times when on-site through the installation.”

Matthew Showering, Managing Director – Brothers Drinks

Solar PV system

Brothers Drinks puts environmental concerns at the forefront of their business efforts, and so a solar PV installation seemed like a natural extension for the company when exploring options to repair the roof of their cider mill, which was leaking and needed replacing. With a compromised roof, high energy costs, and the aim to reduce their carbon emissions, Brothers Drinks approached Solarsense to design, install and maintain a solar PV system for their drinks manufacturing site. Following a detailed technical review and site survey, the design engineers at Solarsense specified 410W REC solar panels with SolarEdge optimisers to maximise on-site energy generation, whilst ensuring the waterproofing system beneath remained intact and without compromise.

The 316.52kWp solar PV system installed on the trapezoidal roof of the cider mill is comprised of 772 solar panels, 3 inverters and 389 SolarEdge optimisers. It will generate approximately 320,199kW hours of clean electricity per year, as well as mitigating more than 67,856kg of carbon emissions annually. This is the equivalent of planting 2,515 trees each year.

By opting for SolarEdge optimisers and online monitoring, Brothers Drinks were able to overcome an issue with shading on their roof caused by nearby trees. In a conventional solar PV system, the solar panels are connected in strings and therefore if one panel is shaded it will affect the output of all the panels in the connected string. In comparison with SolarEdge optimisers, each solar panel or pair of panels operate independently, ensuring the PV system operates to its maximum potential. SolarEdge also offers several enhanced safety features, as well as a detailed monitoring portal to enable businesses to get a full picture of what the PV system is generating, how much energy is being used on-site and what is being exported to the grid. This is particularly useful for Brothers Drinks who are measuring the performance of their solar PV system, whilst they consider installing more solar panels and energy storage in the near future.

As well as significantly improving the sustainability credentials of the factory, the large-scale solar PV system installed for Brothers Drinks is estimated to generate a net profit of more than £3.4million for the company over the next 25-years. Positive early data indicates the solar panels are generating in line with the financial projections and likely to pay for themselves within three years.

Services provided

- Feasibility study including detailed technical design (SolarEdge solar PV system)

- Full supply, installation, commissioning and testing

- Online monitoring portal configuration

- Full handover including MCS registration, G99 grid connection, operation and maintenance pack

Video